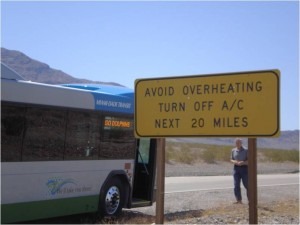

After completing validation for their new Hybrid Beltless Alternator™ (HBA™) in August 2010, Vanner exceeded industry requirements and put their new product through intense climate testing–taking the heat in Death Valley. The testing was important to both Vanner and Allison as the Vanner HBA™ is the critical component in Allison’s H40/50 EP “Smart Electrification” program.

After completing validation for their new Hybrid Beltless Alternator™ (HBA™) in August 2010, Vanner exceeded industry requirements and put their new product through intense climate testing–taking the heat in Death Valley. The testing was important to both Vanner and Allison as the Vanner HBA™ is the critical component in Allison’s H40/50 EP “Smart Electrification” program.

For two full days of performance testing, with temperatures reaching 108 degrees, Vanner, Allison, and Gillig engineers ran the HBA™ tests on full-load and throughout the load range, to ensure that:

- Temperatures on Allison’s transmission stayed well below acceptable tolerances.

- The HBA™ did not discharge the Allison high voltage battery under any conditions, especially low state-of-charge.

- The entire system — Vanner’s HBA™ and Allison’s H 40/50 EP hybrid system — worked efficiently and harmoniously under these harsh conditions.

Allison dictated a high-temperature ceiling from Motor-A in their transmission of up to 200 degrees Celsius. The HBA™ operated flawlessly and remained efficient, never moving the transmission’s Motor-A temperature above 104 degrees Celsius. The Allison / Vanner “Smart Electrification” system performed above all efficiency and operational expectations in the most extreme environmental conditions.

The Vanner HBA™ Story

The Vanner HBA™ replaces the traditional alternator, improves mpg and reduces exhaust emissions, improving air quality. Vanner and Allison “Smart Electrification” eliminates energy dependence and improves energy efficiency for our transit customers. After very successful testing in the hottest region in the United States, the HBA™ production launch is now available as an option on the Allison H 40/50 EP system, from all North American bus OEMs’ in January 2011.

Experience Power…Experience Vanner!

More Information: info@vanner.com

Follow Us on Twitter: @VannerInc